ASTM D5845-16

Standard Test Method for Determination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and tert-Butanol in Gasoline by Infrared Spectroscopy

ASTM D5845 covers the determination of oxygenates such as alcohols and ethers in gasoline by FT mid-infrared spectroscopy.

The method applies to gasoline samples containing methanol from 0.1 to 6 mass %, ethanol from 0.1 to 11 mass %, in samples where triglycerides are detected (from 1 to 10 Vol. %), tert-butanol from 0.1 to 14 mass % and ethers DIPE, TAME, ETBE and MTBE from 0.1 to 20 mass %.

Oxygenates in general can be added to spark-ignition engine fuels as a replacement of toxic organometallic octane boosters like tetra-ethyl-lead (LED)with an additional purpose of reducing SOx and NOx emissions. The new EPA regulations to lower sulfur and increase ethanol with strict control on benzene, olefines, aromatics and RVP are found in the Code of Federal Regulations for TIER III gasoline 40 CFR Part 80.

Standard Specification for gasoline D4814 regulates the composition, quality and properties of these valuable engine fuel formulations.

Reference Documents:

ASTM Standards:

D1298 Test Method for Density, Relative Density (Specific Gravity), or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4307 Practice for Preparation of Liquid Blends for Use as Analytical Standards

D4815 Test Method for Determination of MTBE, ETBE, TAME, DIPE, tertiary-Amyl Alcohol and C1, C4 Alcohols in Gasoline by Gas Chromatography

D5599 Test Method for Determination of Oxygenates in Gasoline by Gas Chromatography and Oxygen Selective Flame Ionization Detection

E1655 Practice for Infrared Multivariate Quantitative Analysis

Other Standards

GC/OFID EPA Test Method – Oxygen and Oxygenate Content Analysis (by way of Gas Chromatography with oxygen-selective flame ionization detection)

Summary of Test Method

This method utilizes a Fourier transform mid infrared spectrometer fitted with a transmission sample cell with a specified path length. A beam of infrared light is passed through the sample and the motion of the spectrometer mirrors enables determination of the sample absorption spectrum. Specific regions of the spectrum where alcohols and ethers show strong absorption are used for the analysis. Users should prepare the sample according to instrument manufacturer instructions after the correct validation and instrumental checks of the instrument.

Calculations take place when a multivariate mathematical analysis is carried out which converts the detector response for the selected regions in the spectrum of an unknown to a concentration for each component.

Figure 1. Eraspec FT-IR Spectrometer

Significance and Use:

Alcohols and ethers are added to gasoline to produce a reformulated lower emissions gasoline and to increase the octane number. Type and concentration of various oxygenates are specified and regulated to ensure acceptable commercial gasoline quality. Driveability, vapor pressure, phase separation, and evaporative emissions are some of the concerns associated with oxygenated fuels.

This test method is faster, simpler, less expensive and more portable than current GC methods. This test method may be applicable for quality control in the production of gasoline. This test method is not suitable for testing for compliance with federal regulations. False positive readings for some of the samples tested in the round robin were sometimes observed. As only extreme base gasolines were tested in the round robin, no definitive statement can be made as to the expected frequency or magnitude of false positives expected in a wider range of base gasolines.

Apparatus

ERASPEC is rugged, robust and portable, can operate off line and at line. Primarily it determines the overall absorption spectrum of the sample in the Middle Infrared region, approximately from 450 up to 6500 cm -1. After a mathematical transformation of the firstly obtained raw interferogram spectrum illustrated in Fig.2, signal is transformed in plots of frequencies vs. absorption intensities. Since all hydrocarbon types absorb in the Mid-IR in a characteristic manner following Beer – Lambert’s Law, the absorption spectrum of bands and intensities can be integrated and related to chemical composition, physical properties and product quality parameters.

The resolution of these systems is typically 4 cm–1 and the noise of the single beam spectrum at 100 % transmission shall be less than 0.3 % peak-to-peak in the region from 1725 cm–1 to 1765 cm–1.

Figure 2. Diagram of the FT_IR Spectrometer

Reagents and Materials

Samples for Calibration and Quality Control Check Solutions—Use of chemicals of at least 99 % purity is highly recommended for preparing calibration standards and quality control check samples. If reagents of high purity are not available, an accurate assay of the reagent must be performed using a properly calibrated GC or other techniques. Base gasolines containing no oxygenates, especially those mentioned in the scope.

Warning—These materials are flammable and may be harmful if ingested or inhaled.

Sampling and Sample Handling

Samples should be taken following procedures described in Standard Practices D4057 & D4177 wherever the case might be. Protect samples from extreme temperatures.

Avoid the use of leaking containers that might affect the sample integrity. Equilibrate sample temperature prior to perform an analysis and reseal the container for future needs. Follow instruction from instrument manufacturer’s operation manual. See for example Eraspec Operation Manual.

Preparation, Calibration and Qualification of the Infrared Test Apparatus

The calibration of the instrument must proceed according to the manufacturer’s instructions. This calibration may be performed by the instrument manufacturer prior to delivery of the instrument to the end user.

The instrument must be qualified according to the procedure in Annex A1 of D5845 method to ensure that the instrument accurately and precisely measures each oxygenate in the presence of typical gasoline compounds or other oxygenates that, in typical concentrations, present spectral interferences. General classes of compounds that will cause interferences include aromatics, branched aliphatic hydrocarbons, and other oxygenates.

Please review recommended concentrations in Table 1 of D5845 for individual quality control.

Quality Control Checks

Prepare standards in mass % according to Practice D4307. The individual oxygenate values obtained must agree within ± 5 % relative of the values in the prepared quality control standard (for example, MTBE 14.0 ± 0.7 mass %) or to within ± 0.3 mass % absolute, whichever is greater (for example, methanol 4.0 ± 0.3 mass %). If the individual values are outside the specified range, recalibrate the instrument according to the procedures in D5845 paragraph 9.2 and Eraspec Operation Manual. The quality control standards should not be used for the calibration or recalibration of the instrument. Samples without meeting the quality control specifications should not be analyzed.

Standard(s) should be prepared in sufficient volume to allow for a minimum of 30 quality control measurements to be made on one batch of material. Properly package and store the quality control samples to ensure that all analyses of quality control samples from a given lot are performed on essentially identical material.

Procedure

Determination of the oxygenate content in Gasoline should proceed according to the Instruction Manual of the manufacturer after sample temperature equilibration. Eraspec comes pre calibrated from the factory. Eraspec automatically also performs a background spectrum used in the calculations. The validation of the instrument and the revision of the IQT parameters should be obtained prior to the introduction of the QC reference standard.

Rinsing of the absorption cell introduction of sample and the rest of the D5845 analysis steps is performed automatically by the Eraspec after the settings parameters and method had been selected.

Calculations

Conversion to Mass % of Oxygenates – To convert the calibration and qualification standards to mass % use Eq.:

mi = Vi (Di /Di)

where:

mi = mass % for each oxygenate

Vi = volume % of each oxygenate

Di = relative density at 15.56 °C of individual components as in Table 2 of D5845

Di = relative density at 15.56 °C of the fuel as determined by Practice D1298 or Test Method D4052. If the density has not been measured, an assumed density of 0.742 should be used.

Eraspec has a built in D4052 Density Module which makes this conversion extremely useful and simultaneous in every run. Results are printed separately and the feed to the calculation software is carried out automatically.

Total mass % Oxygen—Sum the mass % oxygen contents of all oxygenate components determined above according to Eq:

Wtot = Σ[( mi x 16.0 x Ni)/Mi]

where: Wtot = total mass % oxygen in the fuel

mi = mass % for each oxygenate,

16.0 = atomic mass of oxygen,

Ni = number of oxygen atoms in the oxygenate molecule, and

Mi = molecular mass of the oxygenate molecule as given in Table 2 D5845.

Report

Report concentrations of oxygenates in either mass % or Volume % by test method D5845, to the nearest 0.1%.

Precision and Bias

The precision of this test method, which was determined by statistical examination of the results from the interlaboratory study reported in research report RR:D02-1734.

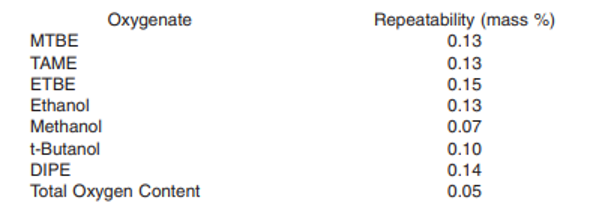

Repeatability (r) – The difference between successive test results obtained by the same operator with the same apparatus under constant operating conditions on identical test samples would, in the long run, and in the normal and correct operation of the test method, exceed the following values only in one case in twenty, where X = the average of two test results.

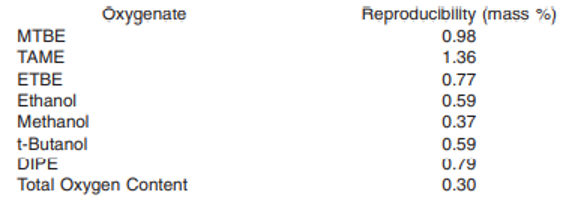

Reproducibility (R) – The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values in only 1 case in 20, where x represents the average of the two consecutive test results.

Bias – No consistent bias was observed from the results of the samples involved in the interlaboratory study.

References

1. D4814 Standard Specifications for Automotive Spark-Ignition Engine Fuel

2. D5845 Standard Test Method Determination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and tert-Butanol in Gasoline by Infrared Spectroscopy

3. ERALYTICS Eraspec – Operation Manual