A complete Automated Method to replace difficult visual quantification.

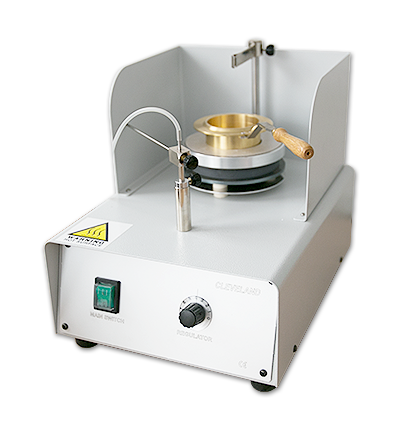

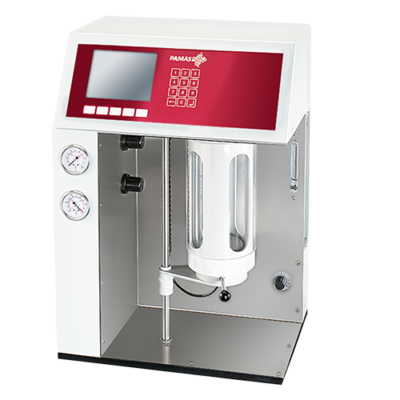

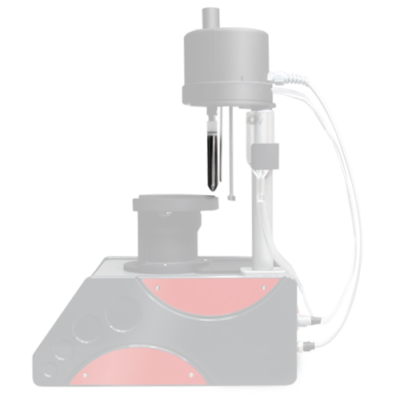

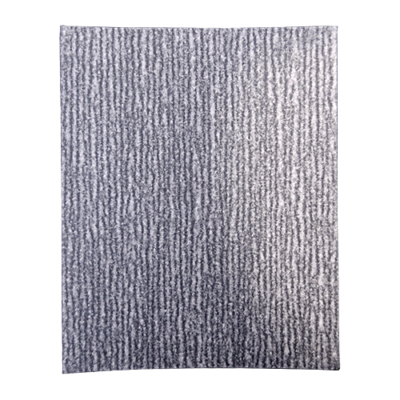

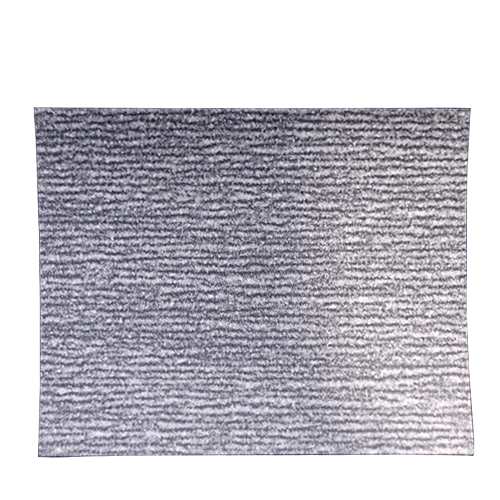

The National Association of Corrosion Engineers (NACE) requires companies to carefully monitor the levels of corrosion by regularly testing the interior of pipes and tanks used in the oil and gas industry. The Iron/Rust Digital Detection Imaging (FeDDI) is here to simplify the laborious process of quantifying the level of corrosion when testing manually. With the FeDDI rust analyzer, you save time, money and resources with our automated method— replacing the inherently difficult visual quantification referenced in NACE testing methods TM0172 and ASTM D665. After scanning a specimen’s entire surface area, corrosion coverage is quantified digitally. It uses our patented four-step automated VISION Algorithm and classification process to eliminate user bias and provide repeatable results. Rust corrosion results you can trust.