From qualified practitioner to quintessential professional, designed with the end user in mind.

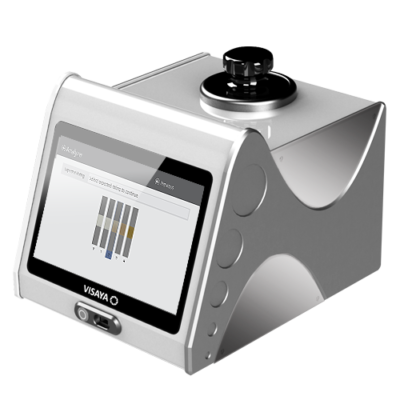

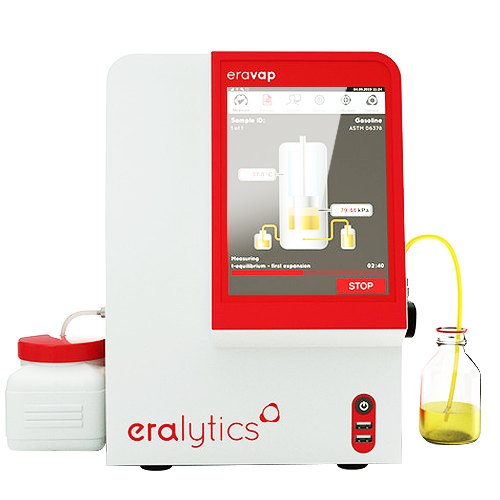

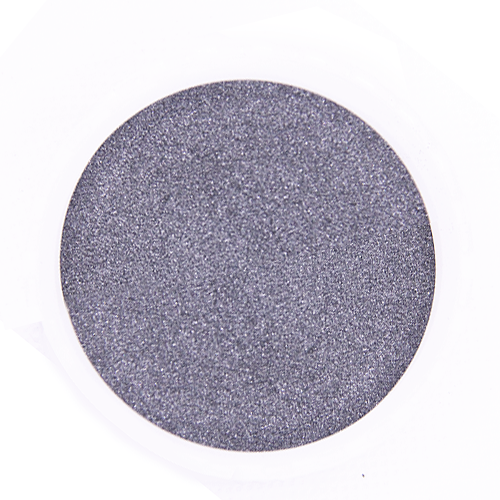

Sulfur-based corrosion is on the rise in the refining industry and the AgDDI is here to help. The Silver Digital Detection Imaging device (AgDDI) from VISAYA uses a four-step automated VISION Algorithm and classification process to eliminate user bias. Ensuring fuel stays within acceptable limits requires constant and accurate corrosion testing equipment. The AgDDI takes the user bias out of the equation. No more having to evaluate corrosivity by interpreting the color and tarnish level of a silver strip soaked in a fuel sample by hand. First, AgDDI identifies the silver strip’s length and width(mm). Next, the algorithm assigns the sample an integer between 0 and 4 representing corrosivity (0 = no corrosion at all & 4 = significant blackening). . AgDDI provides standardization to the current visual silver strip corrosion test as referred in ASTM D7671 and gasoline fuel specification ASTM D4814.