11:30 am – Noon

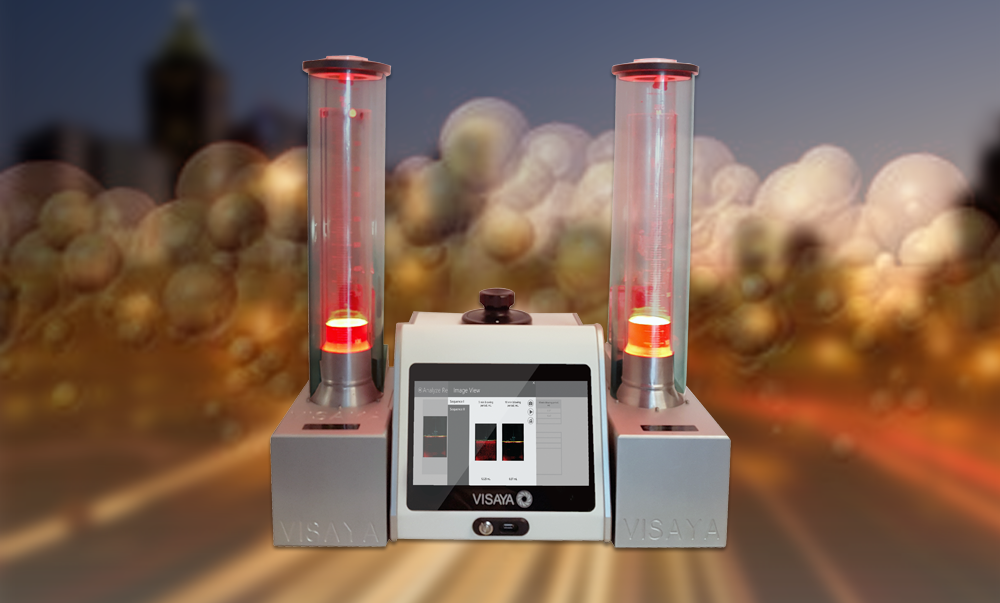

Foam-DDI: Fast, Reliable and Unbiased Determination of Foaming Tendencies of Lubricants by Digital Detection Imaging Aaron Mendez, Ayalytical Instruments, Houston, TX

Oil industry operations are negatively impacted by loss of efficiency of lubricants. They degrade overtime due to: loss of viscosity, oxidation, polar and water contamination and foaming tendency. These characteristics are assessed by ASTM D892 that empirically rates the lubricants. D892 determines lubricants ability to resist foam formation and dissipate foam creation, however D892 is operator-biased, lengthy and render low repeatable and reproducible results. Foam inhibitors eliminate or retard the formation of stable foam, however, it is a challenge that demands precise selection of the defoamant and careful control of optimum concentration. The effect of antifoams and the lubricant properties require continuous, fast response tests that FoamDDI can provide. Foam-DDI accurately controls the air flow, temperature and sequence, using a precise VISION algorithm to determine static and dynamic foam heights, fast and accurately. Repeatability and reproducibility are excellent.