Durability and dependability, one test at a time.

The simple and efficient design of the Viscometer Bath guarantees compliance with ASTM D445, ASTM 446, ASTM D2170, EN 12595, IP 71, IP 319, ISO 3104, and ISO 3105 standards, for determining kinematic viscosities via glass capillary.

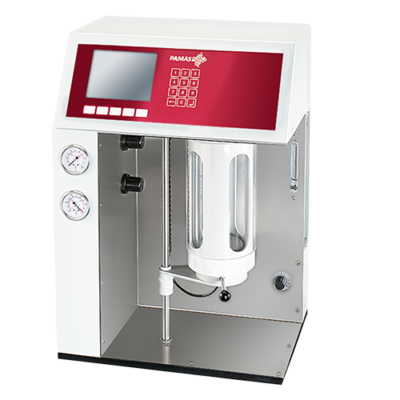

Designed to be safe, accurate, and efficient, the Borosilicate viscosity bath of this viscosity measurement device is equipped with constant digital microprocessor PID temperature regulation and an overtemperature alarm for superior kinematic viscosity measurement. The liquid indicator, visible from the outside of the instrument, allows for easy fill without overflow while the internal light indicator alerts to low liquid levels. The stainless steel electric heating component allows for the quick boiling of liquids while the cooling coil provides improved control near ambient temperatures.

Available in three models, this durable and dependable kinematic viscosity bath covers working temperatures ranging from ambient to 150ºC in models 370 and 390 (high precision), and -30ºC to +60ºC in model 450 (refrigerated). With a capacity of approximately 15 liters, the 15 kg Viscometer Bath is equipped with borosilicate tank, punctured cover, stainless steel standby covers, motorized agitator, tempered glass leakage protection vessel, stainless steel base, and stainless steel control box. The digital thermoregulator PID temperature control maintains ±0.1ºC in the 370 model, and ±0.01ºC in the high- precision 390 and refrigerated 450 models of kinematic viscosity measurement instruments.