Full automation and Elimination of User Bias.

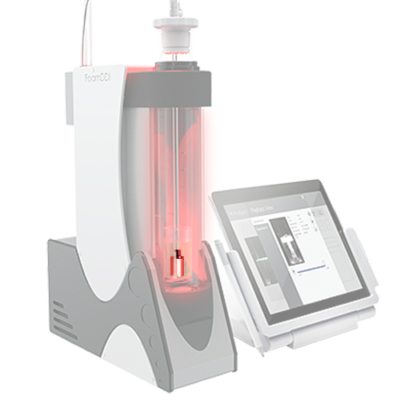

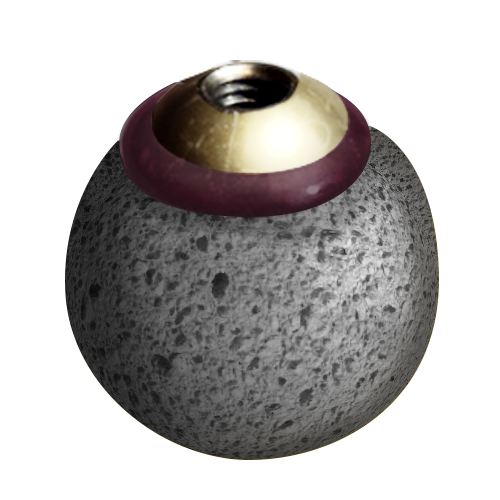

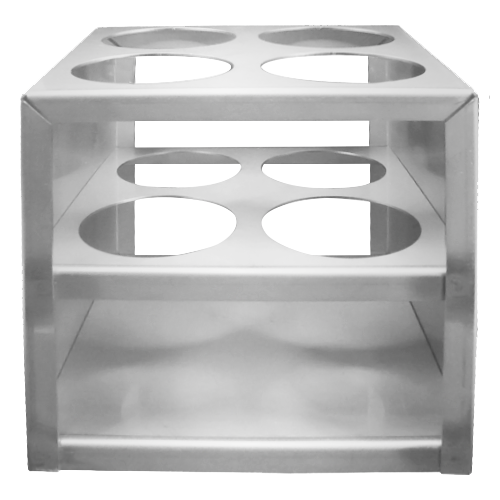

The ultramodern Foam Digital Detection Imaging device (FoamDDI) accurately controls airflow, temperature, and sequencing when testing foam tendencies in oils and lubricants. The fully automatic FoamDDI augments these measurements using our unique VISION Algorithm to accurately determine both the station and dynamic foam heights with precision and accuracy. Relying on the human eye” to measure foam heights is unreliable, time consuming and can be costly due to user bias. The FoamDDI imaging device eliminates these issues and the need for sample manipulation and critical timing involved with other foam detector methods. Using a patented heating and cooling system the FoamDDI records, calculates, and displays accurate results with little to no operation bias. Determinations come from this foam detector in minutes! See also our StoneDDI device.

How it works:

- Using a high-resolution camera with state-of-the-art optics for lubrication testing, FoamDDI quickly brings a sample in the inserted cylinder to test temperature.

- After a soaking time, the foam detector and analyzer insert air for foam production.

- Air Flow is controlled using Mass Air Flow Controllers (MFC)

- At the 5-minute mark, an LED light source is activated.

- VISION Algorithm is activated and begins analysis.

- The complete sequence is recorded and analyzed.

- Test is completed or the next sequence can automatically be continued if desired.