Durable. Dependable. Design you can trust.

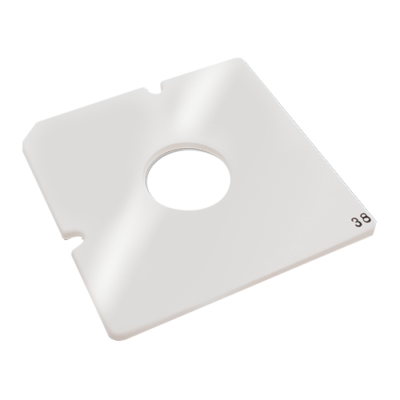

This model is obsolete and replaced with the Tanaka AD-7 automatic distillation analyzer. This automatic distillation apparatus, Model AD-6 automatically performs distillation tests of petroleum products, as well as narrow boiling range samples. Tanaka’s 6th generation model in their distillation of petroleum products series has been developed as an eco-friendly, automated distillation tester, using a Peltier system which does cooling/heating of the condenser, as well as cooling of the cylinder compartment.