Easy use for novice to expert operators.

The simple and efficient design of the Engler viscometer machine guarantees compliance with ASTM D1655, DIN 51 560, and IP 212 standards, for determining kinetic viscosities of tars and their fluid products from ambient temperatures to 100ºC (212ºF).

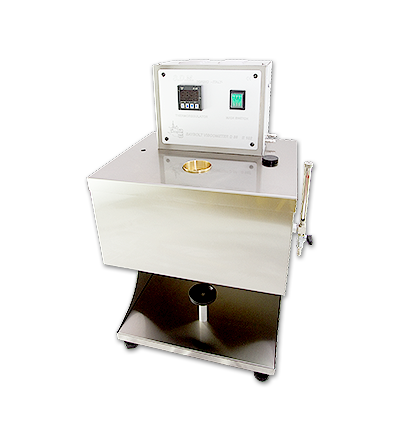

Designed with safety and accuracy in mind, the stainless steel, open jacket Engler viscometer machine is equipped with constant digital micro-processor PID temperature regulation (270 model) or table electronic temperature regulation (conventional model), overtemperature alarm, and an insulated double wall. The liquid indicator, visible from the outside of the Engler Viscometer instrument, allows for easy fill without overflow while the internal light indicator alerts to low liquid levels. A PTFE tipped closing rod permits easy closing of the capillary hole, while the stainless steel electric heating component and cooling coil allow for quick boiling and cooling of liquids in the viscosity machine.

Available in models 260 conventional, 270, and 270/2 (2 positions), and with a capacity of approximately 7 liters, the 12 kg Engler viscometer machine is equipped with brass oil cup with stainless steel flowing orifice, and thermometer support to deliver timely, accurate results. PID temperature control in the 270 model and table electronic temperature regulation in the conventional models maintain ±0.1ºC, providing superior stability. Conventional viscosity machine models are equipped with manual agitators and tripod, while the 270 model comes complete with motorized agitator.