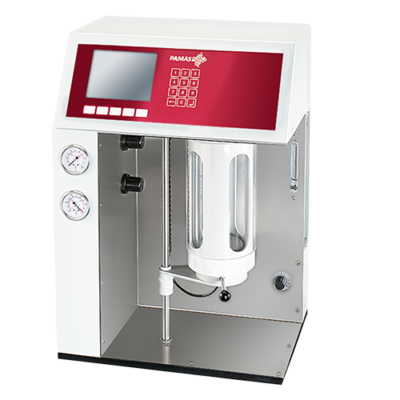

Practical design for the everyday user

ASTM D2112 OXIDATION STABILITY OF INHIBITED MINERAL INSULATING OIL BY PRESSURE VESSEL

This test method covers and is intended as a rapid method for the evaluation of the oxidation stability of new mineral insulating oils containing a synthetic oxidation inhibitor with use of an oxidation stability tester. This test is considered of value in checking the oxidation stability of new mineral insulating oils containing 2,6-ditertiary-butyl para-cresol or 2,6-ditertiary-butyl phenol, or both, in order to control the continuity of this property from shipment to shipment. The applicability of this procedure for use with inhibited mineral insulating oils of more than 12 cSt at 40°C (104°F) (approximately 65 SUS at 100F) has not been established with the oxidation stability of gasoline testers.

ASTM D2272 OXIDATION STABILITY OF STEAM TURBINE OILS BY ROTATING PRESSURE VESSEL

This oxidation stability of gasoline test method utilizes an oxygen ASTM pressure vessel tester to evaluate the oxidation stability of new and in-service turbine oils having the same composition (base stock and additives) in the presence of water and a copper catalyst coil at 150°C (302°F).

ASTM D4842 OXIDATION STABILITY OF GASOLINE AUTOMOTIVE ENGINE OILS BY THIN-FILM OXYGEN UP TAKE (TFOUT )

This test method evaluates the oxidation stability of engine oils for gasoline automotive engines with an oxidation stability tester. This test, run at 160°C (320°F), utilizes a high-pressure reactor pressurized with oxygen along with a metal catalyst package, a fuel catalyst, and water in a partial simulation of the conditions to which an oil may be subjected in a gasoline combustion engine. This ASTM oxidation stability tester can be used for engine oils with viscosity in the range from 4 mm2/s (cSt) to 21 mm2/s (cSt) at 100°C (212°F), including re-refined oils.

ASTM D7098 OXIDATION STABILITY OF LUBRICANTS BY THIN-FILM OXYGEN UP TAKE (TFOUT) CATALYST B

IP 229 DETERMINATION OF THE RELATIVE OXIDATION STABILITY BY ROTATING BOMB OF MINERAL TURBINE OIL

This standard specifies a method for the estimation of the oxidation stability of unused turbine oils having the same composition (base stock and additives) and for controlling the continuity of this property from batch to batch.

The following accessories are recommended for purchase in sequential order (see eStore):

1st Year:

COPPER CATALYST, pack of 5 pcs x4

CATALYST A”, pack of 3 kit (ASTM D4742) For about 39 test

CATALYST B”, pack of 3 kit (ASTM D7098) For about 39 test

SILICON CARBIDE ABRASIVE CLOTH 100 GRIT, pack of 25 m x2

CHART FOR RECORDING MANOMETER, 0-200 psi pack of 100 pcs x4

PENS FOR RECORDING MANOMETER, pack of 10 pcs x1

O-RING VITON FOR COVER, pack of 10 pcs x1

O-RING PTFE FOR STEM, pack of 10 pcs x1

2nd Year:

Same as 1st year

Remaining Parts:

PROBE PT100A

DIGITAL THERMOREGULATOR

STATIC RELAY

BIPOLAR GREEN SWITCH

BIPOLAR YELLOW SWITCH

MOTOR STIRRER

For ASTM D2112

OXIDATION VESSEL RPVOT (RBOT)/TFOUT Made of stainless steel AISI 316L. Complete of a lid, cap, stem and needle valve ¼”. Tested at 100 bar / 1450 psi @25°C

RECORDING MANOMETER Chart, 0-200 psi

DIGITAL MANOMETER 30 bar / 435 psi / 3000 kPa, data logger, RS232C

CERTIFICATE DIGITAL MANOMETER 30 bar / 435 psi / 3000 kPa, data logger, RS232C

SAMPLE CONTAINER Made of glass, 175 ml, for copper catalyst

GLASS COVER Ø50.8 mm.

COPPER CATALYST, pack of 5 pcs L=3 m.

SILICON CARBIDE ABRASIVE CLOTH 100 GRIT, pack of 25 m

SILICONE OIL 50 cSt, pack of 25 kg For temperature from 100°C (212°F) to 200°C (392°F)

ELECTRONIC BALANCE Range 200 g, readout 0.01, pan Ø130

THERMOMETER ASTM 96C

For ASTM D2272

OXIDATION VESSEL RPVOT (RBOT)/TFOUT Made of stainless steel AISI 316L. Complete of a lid, cap, stem and needle valve ¼”. Tested at 100 bar / 1450 psi @25°C

RECORDING MANOMETER Chart, 0-200 psi

DIGITAL MANOMETER 30 bar / 435 psi / 3000 kPa, data logger, RS232C

CERTIFICATE DIGITAL MANOMETER 30 bar / 435 psi / 3000 kPa, data logger, RS232C

SAMPLE CONTAINER Made of glass, 175 ml, for copper catalyst

PTFE DISK Ø57.2×1.6 mm., with 4 holes Ø3.2 mm.

HOLD-DOWN SPRING Between PTFE disk and oxidation vessele for ensure rotation of the sample container

COPPER CATALYST, pack of 5 pcs L=3 m.

SILICON CARBIDE ABRASIVE CLOTH 100 GRIT, pack of 25 m

SILICONE OIL 50 cSt, pack of 25 kg For temperature from 100°C (212°F) to 200°C (392°F)

ELECTRONIC BALANCE Range 200 g., readout 0.01, pan Ø130

THERMOMETER IP37C

For ASTM D4742 D7098

OXIDATION VESSEL RPVOT (RBOT)/TFOUT Made of stainless steel AISI 316L. Complete of a lid, cap, stem and needle valve ¼”. Tested at 100 bar / 1450 psi @25°C

RECORDING MANOMETER Chart, 0-200 psi 10-MANDIG/30 DIGITAL MANOMETER 30 bar / 435 psi / 3000 kPa, data logger, RS232C 10-MANDIG/30/C CERTIFICATE DIGITAL MANOMETER 30 bar / 435 psi / 3000 kPa, data logger, RS232C

ALUMINUM INSERT Ø6.03×7.46 cm

SAMPLE CONTAINER Made of glass

PTFE COVER Ø57.2×0.8 mm., with central hole Ø3.2 mm.

HOLD-DOWN SPRING Between PTFE disk and oxidation vessele for ensure rotation of the sample container

CATALYST A”, pack of 3 kit (ASTM D4742) For about 39 test

CATALYST B”, pack of 3 kit (ASTM D7098) For about 39 test

SILICONE OIL 50 cSt, pack of 25 kg For temperature from 100°C (212°F) to 200°C (392°F)

ELECTRONIC BALANCE Range 160 g., readout 0.001, pan Ø110

THERMOMETER ASTM 102C